Sources of VOCs :

Effects of VOC :

- Adverse Effects on Health such as Respiratory & Eye related problems.

- Negative Impact on Environment such as Depletion of Ozone Layer, Smog, etc.

- Unaccounted Monetary Loss.

Our AIM :

We, Trinamo Environmental India have created a product with our expertise, the Vapor Recovery Unit specially designed for Petroleum Storage Depots, Terminals & Petrochemical Refineries.

Our foremost objective is to save our environment as well as help our clients in cutting their carbon footprint and monetary loss.

Our Expertise - VRU :

The VRU minimizes the release of Hydrocarbon Vapours directly into the environment, processing it back to liquid gasoline using a process which comprises of Condensation & Membrane Technology.

Technologies We Used

- Condensation + Membrane Technology

- Condensation + Membrane + Adsorption Technology

Membrane Technology :

This is our Patent Technology which we use to separate the retentate stream (which is of reduced hydrocarbon) and permeate stream (which is rich in hydrocarbon) by creating the Pressure difference across the membranes.

The permeate stream is recycled to the inlet of the compressor, where it mixes with the inlet vapor to create an enriched vapor stream and the retentate stream goes to the Vent.

Condensation Technology :

We use this technology in condensing the compressed vapor coming from the MS Compressor via Pre-cooler & Cooler (Shell & Tube Type Heat Exchanger) which further gets condensed into Gasoline (Liquid State) and collected in the Storage Tank.

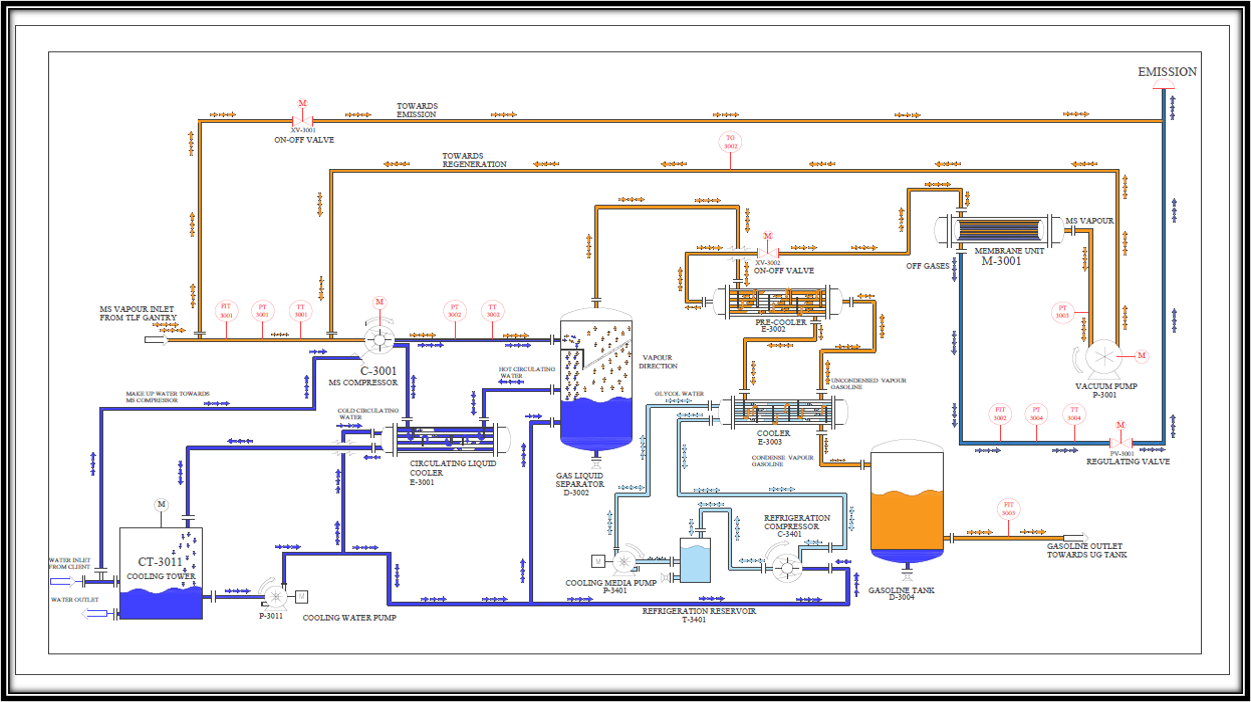

Process Flow Diagram :

Process Flow Description :

- Vapor coming out during Tank truck Loading operation comes to the inlet of the VRU at Atmospheric Pressure & temperature. At the inlet of VRU, we have placed Trap Tank which is used to trap Liquid/Gasoline which may come with vapor into the system. We have used the Vortex Flow Meter also to measure the inlet flow of vapor.

- Vapor further goes into the Inlet Filter, which is of cartridge type, in case of any solid particles come along with vapor, it gets filtered.

- The vapor coming out from the filter enter at the suction of the Compressor which is water injected z-screw type compressor.

- We are injecting the water to maintain the temperature since, after the compression process, the pressure & temperature of vapor rises rapidly.

- The Compressed vapor along with water having high pressure and atmospheric temperature enters the Gas-Liquid Separator, where separation of vapor from water takes place. Since, the density of vapor is less than that of water, it goes upwards and the water remain at the bottom of Gas Liquid separator.

- The vapor goes further for the Condensation process and the water goes for Re-circulation in the system from Compressor to Gas liquid Separator through Circulating Liquid Cooler.

- In Circulating Liquid Cooler, we are using the cooling tower to maintain the Re-circulating Water temperature.

- In the Condensation process, vapor enters at the shell side of the Pre-cooler and from Pre-cooler, it goes to the shell side of the Cooler so that we can recover the maximum amount of vapor by converting it into Gasoline.

- To condense the vapor, we are using Mono Ethylene Glycol at -2 to 5 deg. Celsius. & The condensed gasoline gets collected in the Gasoline Tank.

- To maintain the temperature of MEG, we are using Chiller unit.

- The Uncondensed vapor goes for the separation process through the tube side of Pre-Cooler & enters into the Membrane Unit.

- The separation process occurs at the Membrane Unit where permeate stream of vapor rich in Hydrocarbons recycled to used further at the inlet of the Compressor to maximize the efficiency of our system & the retentate stream of vapor consisting of a smaller number of hydrocarbons vent out from the Exhaust directly into the surrounding air.

- Since, it is a closed system so no leakage of vapor will observe during operation of VRU for safety purpose we are using Gas Detector to detect if by any chance there is any leakage.

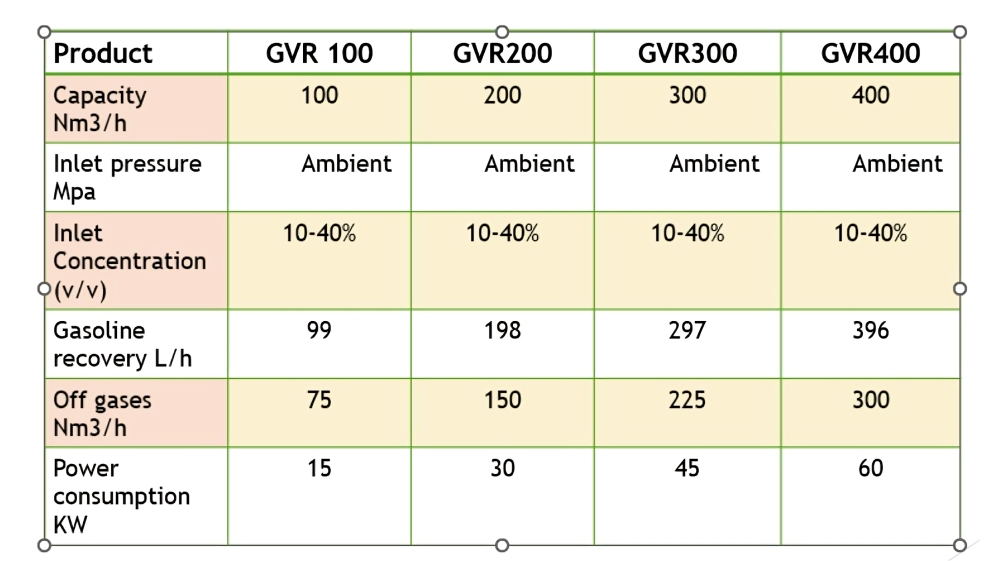

Product Classification :

Note: The Gasoline Recovery & Off gas were calculated on 25% Inlet gasoline concentration.

Product Classification

- Fulfills all the environmental norms applicable in India as well as worldwide.

- Achieve Emission level less than 5 gm /cum.

- The results (gasoline in liquid form) can be measured theoretically as well as virtually without the help of any tool, instrument or complex calculations.

- Keeps track with newest technology resulting in a Small and Compact system rather than old Conventional setup.

- Follow all major international standards used in Oil & gas industry.

- PESO certified System.

- Is capable and versatile as it can handle Top loading and Bottom Loading facility at depots and terminals with ease.

- Is equipped with Flame & explosion proof systems.

- Has Completed number of operational VRU Projects in INDIA & Abroad.

- Our process is the sole process approved by Projects & Development India Limited.

- Capable of processing other hydrocarbons such as benzene & toluene with modifications.